Fortified Rice Making Machine: Revolutionizing Nutrition Enhancement

In the realm of food technology aimed at combating global malnutrition, fortified rice making machines stand as a pivotal innovation. These machines play a crucial role in enhancing the nutritional value of rice by fortifying it with essential vitamins and minerals. Let's explore the significance, functionality, and impact of fortified rice making machines in detail.

Rice is a staple food for a significant portion of the world's population, particularly in Asia and parts of Africa. However, traditional rice lacks essential nutrients, such as iron, zinc, folic acid, and vitamins (A, B12, D), which are crucial for human health and development. Deficiencies in these nutrients can lead to various health issues, especially in vulnerable populations like children and pregnant women.

Fortified rice addresses this nutritional gap by incorporating these vital nutrients into the rice grains during processing, without significantly altering its taste or cooking properties. This innovation helps combat micronutrient deficiencies on a large scale, promoting better health outcomes across communities.

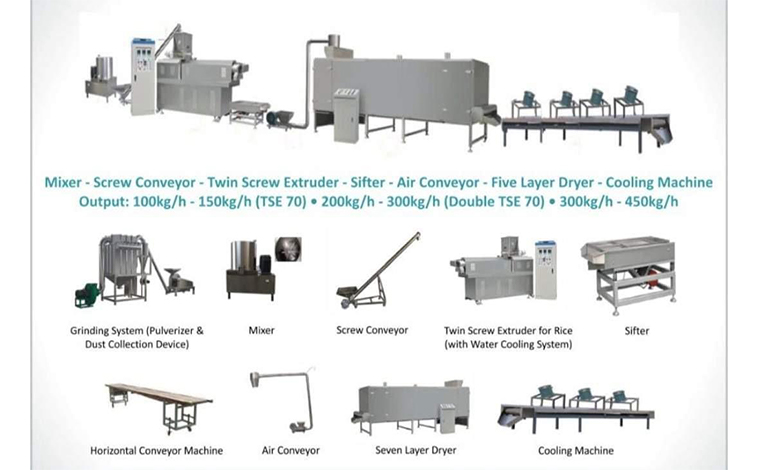

Fortified rice making machines are designed to efficiently and accurately mix micronutrient premixes into rice grains. Here’s a simplified overview of their operation:

Preparation of Premix: A premix containing vitamins and minerals is prepared according to specified formulations recommended by health authorities or nutrition experts.

Mixing Process: The rice and premix are mixed together in precise proportions to ensure uniform distribution of nutrients across all grains.

Coating or Infusion: Depending on the machine design, the nutrient premix can be coated onto the rice grains or infused into them through vacuum technology, ensuring that each grain receives the appropriate amount of fortification.

Drying and Packaging: After fortification, the rice undergoes drying to remove any moisture added during the fortification process. It is then packaged for distribution and consumption.

Fortified rice making machines offer several advantages and applications:

Scalability: These machines can process large quantities of rice efficiently, making them suitable for addressing nutritional deficiencies on a mass scale in countries with high rice consumption.

Nutrient Retention: The technology ensures that the added nutrients are retained within the rice grains, maintaining their bioavailability and effectiveness.

Customization: Machines can be adjusted to fortify rice with different combinations and concentrations of nutrients based on regional dietary needs and health priorities.

Public Health Impact: By fortifying rice with essential nutrients, these machines contribute to improving public health outcomes, reducing the prevalence of nutritional deficiencies, and supporting overall well-being.

The deployment of fortified rice making machines is part of broader global initiatives to combat malnutrition and improve food security. Governments, international organizations, and NGOs collaborate to promote the adoption of fortified rice as a cost-effective and sustainable strategy for enhancing nutrition.